*Please Note: These tests and procedures are to be performed by a qualified technician only*

The blower is an essential part of your heater and without it, your heater will be unable to function properly.

The blower’s main function is to remove the exhaust and combustion air from the heater and push it through the venting system and outside the building. The blower is one of the first parts of the heating operation to turn on and start working. The reason it is one of the first to turn on is so that it can rid the heater of any excess gas that may result from the trial for ignition. When the trial for ignition begins, the pressure switch will close and the igniter will either spark or glow (depending on the type of igniter your heater has) and the gas valve will open, release gas. If everything is working properly, the gas will be ignited and the burners will be lit. If everything is NOT working properly, however, it is important that the blower is operating correctly to expel any lingering gas.

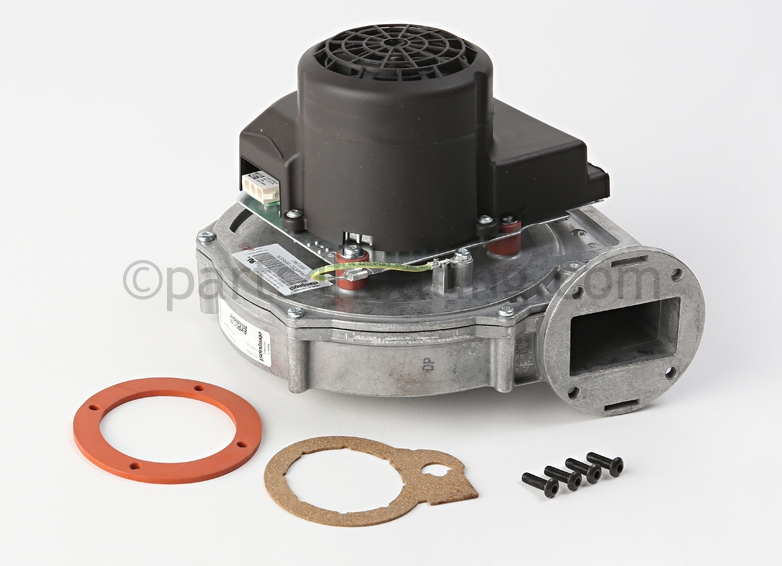

Blowers are primarily comprised of a fan and a motor. These motors are supplied with 120V power. If you suspect your blower may be malfunctioning there are a few things you can check.

With your heater off and the electrical power to the heater also turned off, hold your hand up to the motor side of the blower. If you notice that the motor is very hot, it could be a sign that your blower has been trying to run unsuccessfully and is wearing itself down and creating heat. This could also be the result of a bad capacitor. Check the squirrel cage on the opposite end of the blower as well. If you try and spin it very gently, notice if it spins easily. If it has any resistance or spins sluggish, that could be an indication that the blower is clogged up or is bad. Next make sure all of the wires connecting to your blower and the control board are tight and not loose. This could rule out any issues that would arise from a loose connection.

If the motor is not very hot and the squirrel cage moves freely, the issue could lie in the control board for the heater. In order to check this, locate your blower wires and what ports they connect into on the control board. Find the wire that goes from the blower and into the heat port on the control board, as well as the wire that goes from the blower to the circulating port and unplug both. Using an ohm meter, set to volts (and with the power to the heater on), ensure that the ohm meter is reading 120 volts from those two control board ports. This means the blower is receiving power. If the ohm meter reads 0 or less that 120 volts, then the control board is not sending enough power to the blower and the control board is defective. If the ohm meter is reading 120 volts and the blower doesn’t run, then the blower motor is defective or the capacitor is bad.

You can also check for 120 volts by plugging the leads into the back of the connection plug that joins the blower wires to the rest of the heater and initiate a call for heat. Turn the heater back on and if the blower runs, it will display a voltage reading. Compare that reading to the recommendations above.

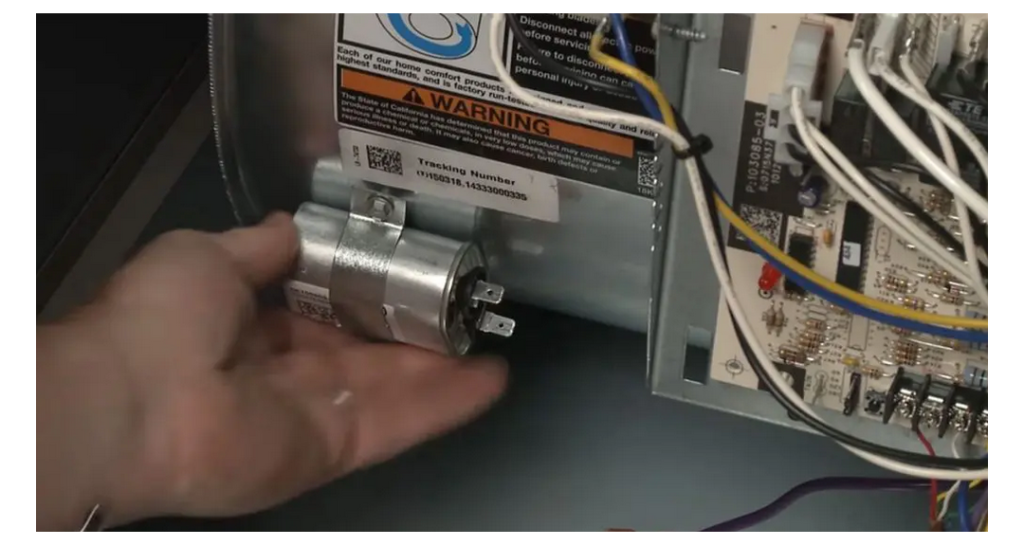

In order to check the capacitor, you will need to first disconnect the wires running to it. If there is anything leaking out of the capacitor, you do not need to check it as it is already bad and needs to be replaced. Make sure that the power to the heater is off. Even with the heater off and no electricity running, a capacitor may still hold an electrical charge. Due to this, you will need to short the capacitor out and discharge that current. You can do this by lightly touching a screw driver to the terminals of the capacitor. Check the label on your capacitor for the reading in microfarads (denoted by a uF) and the tolerance reading, which is the percentage number next to the microfarad reading. The combination of these two numbers (the uF reading plus the percent and the uF reading minus the percent) gives you a range that your capacitor can function properly at without harming the motor of the blower. You will need a tester that is able to measure capacitance or microfarads. Set the tester to read capacitance or microfarads and use the leads to get a reading. Compare the number on the tester and see if it falls within the tolerance range from above. If it is reading outside of the range, it’s a good idea to get your capacitor replaced. If you DO need to replace your capacitor, make sure the new capacitor has the same microfarads reading as your old capacitor. Remember to reconnect any wires you had disconnected before starting up your heater.